Introduction: Understanding Code Is the First Step to a Safe Dryer Vent

Dryer vent installations are governed by building and mechanical codes to protect safety, performance, and building durability. In New Jersey, where housing types vary from historic masonry rowhomes to modern townhouses and single-family residences, code literacy ensures the vent is routed, supported, and terminated correctly. The safest path to compliance and dependable performance is professional dryer vent installation guided by current code requirements and manufacturer instructions. This article explains key code themes and practical implications so you can recognize a compliant, high-performing installation.

Core Concepts: What Codes Aim to Achieve

- Life safety: Reduce the risk of fire from lint accumulation and overheating.

- Performance: Maintain adequate airflow for efficient drying and appliance health.

- Durability: Prevent moisture problems and damage to building materials.

- Compatibility: Ensure installations align with manufacturer specifications.

Key Materials Requirements

Most codes require smooth-walled metal duct for concealed or long-run sections of the dryer exhaust. The interior must be free of obstructions; that means avoiding screws that protrude into the airstream, which snag lint and impair flow. Inside finished walls and ceilings, plastic or thin foil flex is not appropriate. A short, UL-2158A–listed transition connector may be used between the dryer and the wall to allow movement for servicing, but this section should be as short and as straight as practical.

Length Limits and Equivalent Length

Codes and manufacturers set maximum allowable lengths for dryer vents. The limit depends on the number and type of fittings used. Elbows add to the effective length, sometimes significantly, so a vent that is short “as the crow flies” can exceed limits if it twists and turns. A compliant installation calculates total equivalent length before work begins and designs the route to stay within the permitted range. If it cannot, a listed booster fan with automatic activation may be evaluated according to code and manufacturer requirements.

Joints, Fastening, and Sealing

Joints should be assembled with crimped ends oriented to the airflow direction to reduce lint-catching edges. Penetrating fasteners that protrude into the interior are avoided. Exterior seams are sealed with foil HVAC tape, not cloth duct tape, which degrades in heat. Long horizontal runs are supported at intervals to prevent sagging that traps lint and moisture. Attention to these details ensures longevity and consistent performance.

Prohibited Terminations and Locations

- No termination into attics, crawlspaces, garages, or indoor areas. The vent must exhaust outdoors.

- No screens that restrict lint discharge at the exterior outlet. Purpose-built guards and dampers are used instead.

- No connection to chimneys or combined vents serving other appliances.

- Maintain clearances from doors, windows, and fresh air intakes according to code and manufacturer instructions.

Exterior Hoods and Backdraft Dampers

An exterior termination must include a backdraft damper that opens fully during normal dryer operation and closes when idle to keep out pests and weather. In New Jersey’s coastal and winter conditions, robust materials and proper flashing are essential. The hood should be installed level and secure, with sealants appropriate to the cladding, whether vinyl, fiber cement, stucco, brick, or stone veneer.

Roof vs. Wall Termination Considerations

Both approaches can meet code when done correctly. Roof terminations require purpose-built caps and careful flashing to prevent leaks. In snow-prone areas, the cap location and height are chosen to avoid burial by drifts. Wall terminations are often simpler and pose less resistance, but they must maintain required clearances and be protected from landscaping or other obstructions.

Fire-Resistance and Multi-Family Details

Townhouses, condos, and apartments may require penetrations through fire-resistance–rated assemblies. These require approved firestopping methods and materials. Where vents pass through multiple units or common spaces, coordination with building management is necessary. A compliant installation includes documentation of fire stops and seals, as well as identification of accessible service points for future maintenance.

Manufacturer Instructions and Code

Codes generally defer to the appliance manufacturer when instructions are more restrictive. That means the dryer’s installation manual is a critical part of compliance. If the manual specifies a shorter maximum length or prohibits certain fittings, those instructions govern. A knowledgeable installer aligns the route with both code and the specific dryer model’s requirements.

Airflow Verification and Documentation

While code focuses on installation details, performance confirmation is equally important. After installation, the system should be tested under operation to verify strong, stable airflow and full damper travel. Documentation—photos of concealed duct sections and a sketch of the route—helps future technicians and homeowners maintain the system and identify changes over time.

Common Code Violations in the Field

- Use of flex duct inside walls and ceilings.

- Excessive equivalent length without accounting for elbows.

- Termination into attics or garages to avoid a challenging exterior penetration.

- Screens installed at the outlet, causing severe lint build-up.

- Loose, unsupported ducts that sag and collect moisture.

New Jersey Environmental Factors and Code Compliance

Cold winters and coastal storms stress exterior terminations and create condensation potential. Code-compliant installations add insulation in unconditioned spaces where appropriate and secure flashing to withstand wind-driven rain. In dense neighborhoods, clearances from openings and property lines are checked carefully. These local realities make it especially important to work with teams that understand the region’s conditions.

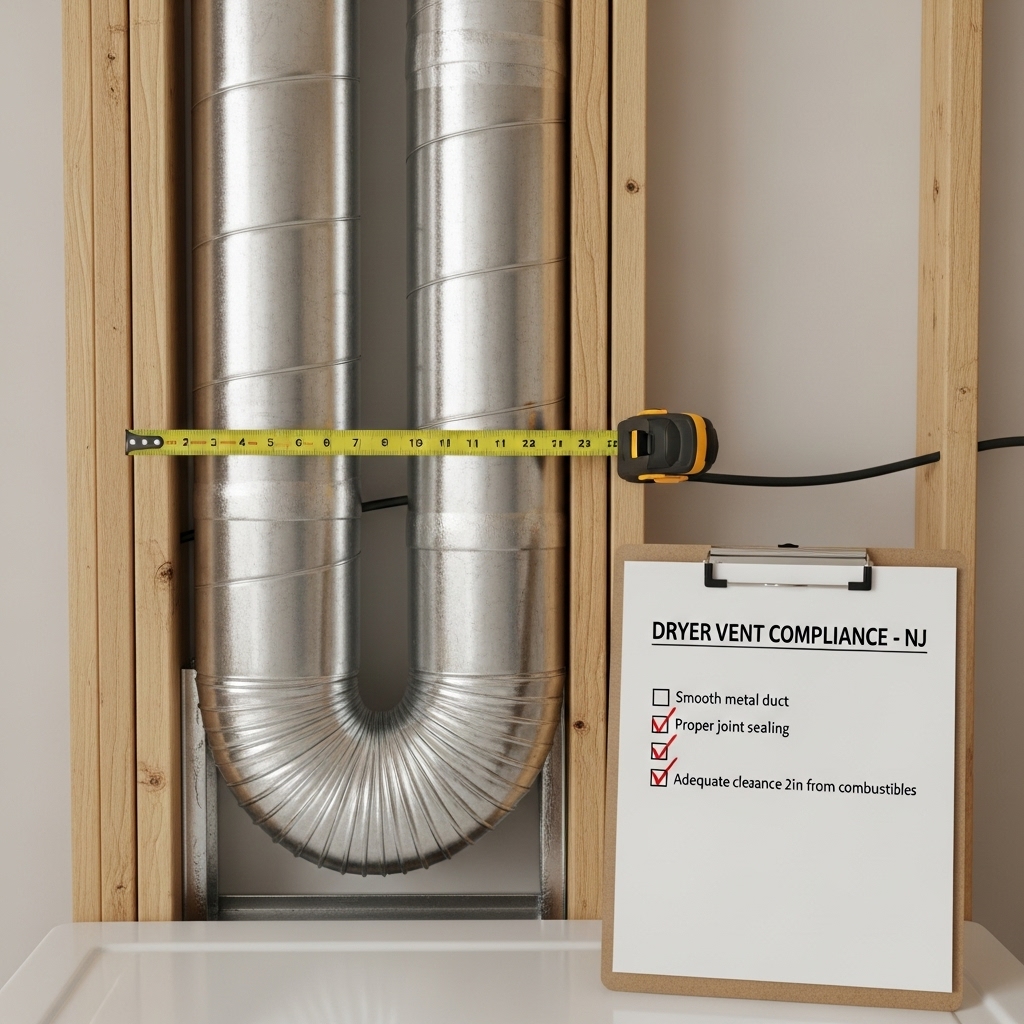

Mid-Article Compliance Checklist

- Rigid metal duct for concealed runs; UL-2158A transition at the dryer only.

- Calculated equivalent length with elbow allowances.

- Joints oriented to airflow and sealed externally with foil tape.

- Proper support spacing to prevent sagging.

- Outdoor termination with a low-resistance damper and no screens.

- Flashing and sealants appropriate to cladding and climate.

- Documentation and airflow verification at completion.

Homeowner Responsibilities

Even a perfect installation can degrade without maintenance. Clean the lint screen after every cycle, inspect the exterior hood seasonally, and schedule professional cleaning as usage requires. If you see paint flaking near the termination, dampness on nearby surfaces, or a damper that no longer opens fully, address the issue promptly to remain aligned with both safety and performance expectations.

Frequently Asked Questions

Q: Is flexible foil duct allowed for the entire run? A: No. Flexible foil or plastic is not suitable for concealed or long runs. Use smooth, rigid metal duct for the primary route and a short UL-listed transition at the dryer.

Q: What determines maximum vent length? A: Both code and the dryer manufacturer’s specifications. Elbows and fittings add to equivalent length and must be included in calculations.

Q: Can I add a screen to keep pests out? A: Standard screens are not recommended because they trap lint and restrict flow. Use a termination designed for dryer exhaust with an effective backdraft damper.

Q: Do I need a permit for a new penetration? A: Requirements vary by municipality and project scope. Consult local authorities or a professional who regularly works in your jurisdiction.

Q: Are roof terminations compliant? A: Yes, when installed with a purpose-built roof cap, correct flashing, and attention to snow and wind exposure. Wall terminations are often preferred when site conditions allow.

Q: What about booster fans? A: If the calculated equivalent length exceeds limits, a listed booster fan with automatic activation may be considered. It must be installed per code and the manufacturer’s instructions.

Q: How do I verify performance? A: Observe full damper opening during operation and request airflow measurements or verified tests at completion. Documentation helps track future changes.

Putting It All Together

A code-compliant dryer vent is the product of careful planning, quality materials, and attention to detail at every joint and penetration. It is also the product of region-specific know-how that accounts for New Jersey’s climate and building practices. With these elements in place, you get consistent drying performance and peace of mind that the installation aligns with safety standards.

Ready to align your project with code and best practices?

If you want compliance and performance in one package, schedule professional dryer vent installation guided by current standards and tailored to New Jersey homes. You’ll gain reliable airflow, durable materials, and clear documentation for your records.