Dryer vent cleaning is one of the most effective ways to protect your New Jersey home, extend the life of your dryer, and keep laundry day efficient. Yet many homeowners wonder how providers shape a proposal for this work and what factors influence the scope of a visit. This guide clarifies the elements that professionals consider when preparing a plan, explains what a thorough service includes, and outlines how to compare providers on quality, not just speed or convenience. You will also learn how to prepare for an appointment and how to maintain strong performance afterward. If you are exploring options right now, reviewing a trusted local team that focuses on comprehensive dryer vent cleaning can help you understand what is typically involved.

What shapes a professional proposal

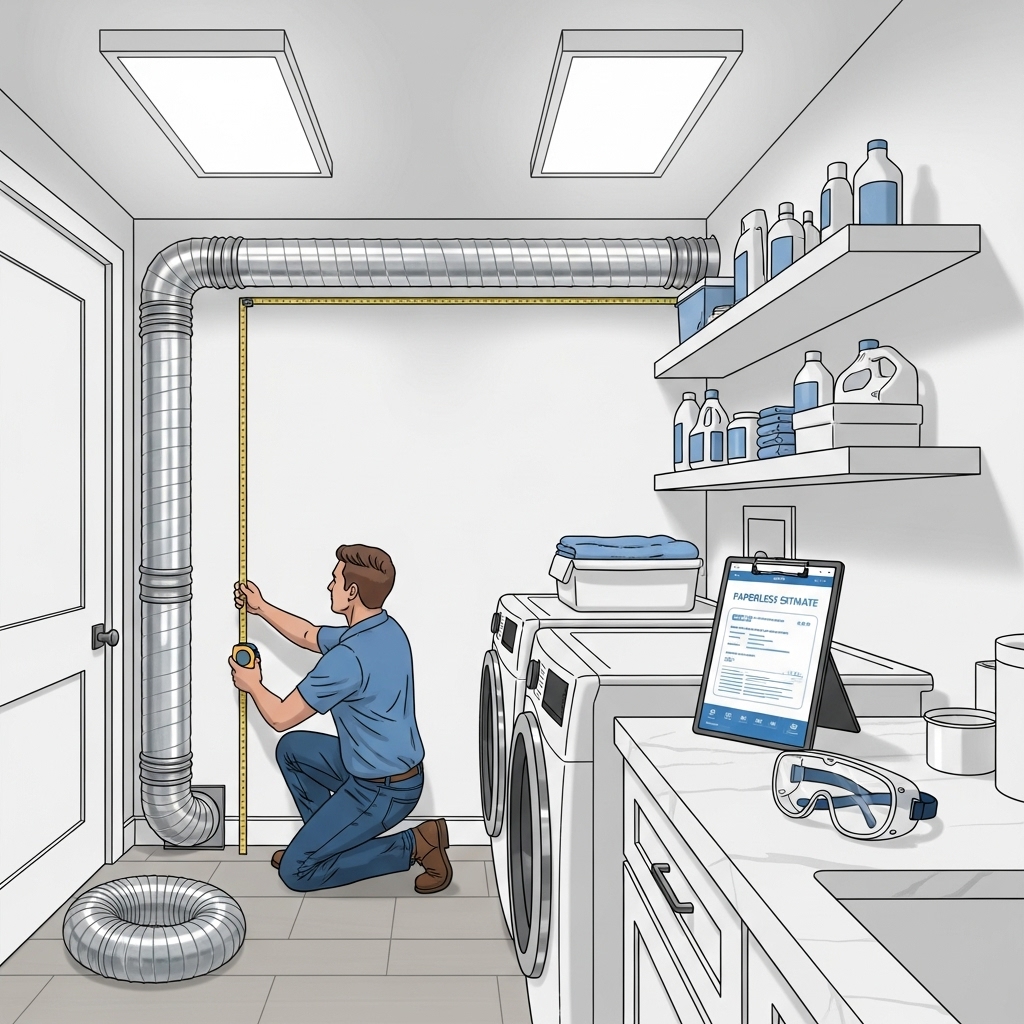

Every home’s vent system is unique, and the details of that system determine the scope of work. A straightforward, short run through an exterior wall requires different time and tools than a long interior run that rises through a ceiling, traverses joists, and terminates at a roof cap. Technicians evaluate the route, the number of bends, the type of termination, and the materials in use. They also note access considerations such as attic or roof entry, tight laundry closets, or stacked washer-dryer units.

The condition of the system matters, too. Homes that have not had maintenance in years may have more lint accumulation, minor blockages at elbows, or a partially stuck damper at the exterior hood. Some properties have outdated materials like thin foil flex behind the dryer, or they may have a crushed connector that needs to be corrected. A thoughtful plan accounts for inspection, cleaning, addressing obvious safety concerns, and verifying airflow improvement at the end.

What a thorough visit includes

A complete cleaning typically covers several steps. First is a quick but careful inspection to confirm the route and identify any concerns. Next, the dryer is pulled forward as needed and the transition hose is disconnected. The technician uses specialized agitation tools—rotary rods with protective brushes or high-velocity air systems—to loosen and collect lint from the entire duct. The internal lint cavity and blower area inside the dryer are addressed where safe and appropriate. Outside, the termination hood is cleared and checked for free damper movement. Finally, the system is reassembled, the dryer is leveled, and an airflow check confirms improvement.

Documentation helps you understand the results. Before-and-after photos of key areas, notes about materials and recommendations, and a brief explanation of the final airflow check provide transparency. If upgrades are advised—such as replacing an unsafe transition material or resealing joints with appropriate foil tape—the technician will explain the reasons clearly.

Home and building variables common in New Jersey

New Jersey’s housing stock introduces several recurring variables. Older homes may have retrofitted vents that snake through basements or crawlspaces; newer homes often use long, interior routes to roof terminations. Townhomes may have shared chases that require careful tool selection, and shore properties contend with windy conditions and salt air at the termination. High-rise buildings and stacked laundry setups require compact equipment and considerate scheduling. Local experience helps technicians anticipate and plan for these conditions.

Comparing providers on quality

When evaluating providers, focus on methodical process and clear communication. A reliable company explains the steps they will take, uses purpose-built tools, protects floors and finishes, and verifies improvement at the end. They can discuss materials knowledgeably, advise on safer configurations, and demonstrate damper operation outside. Look for a provider that emphasizes safety, documentation, and homeowner education rather than a quick in-and-out approach.

Scope variables that influence the work

Several tangible factors shape the scope: the length of the run, the number and tightness of elbows, the presence of roof or hard-to-reach terminations, any evidence of nesting wildlife, and whether inappropriate materials must be replaced. The condition of the dryer’s internal lint pathways also affects how much work is needed. Access considerations—such as a laundry closet with minimal clearance or an attic hatch—play a role as well. Each of these factors can add steps to the process and extend the visit.

What should not be part of the system

There are items that do not belong in a safe, efficient dryer exhaust. Avoid plastic or paper-thin flex for the primary run. Screens that trap lint at the exterior hood can clog quickly and should be avoided. Fasteners that protrude into the duct can snag fibers and lead to buildup. When these issues are found, a qualified technician will recommend durable, code-conscious alternatives.

Value signals beyond the basics

Some providers demonstrate extra care that sets them apart. They show you how freely the damper moves after cleaning and how strong the discharge feels at the termination. They make thoughtful recommendations tailored to your home’s layout and laundry habits. They help you select a maintenance interval that keeps performance steady throughout the year. This attention to detail often results in shorter dry times, a cooler laundry area, and longer service life for the dryer.

How to prepare for your appointment

Make the visit efficient by clearing a path to the laundry area and ensuring the dryer can be moved. Remove items from on top of the appliance and from the surrounding floor. If the termination is on a patio or deck, create access by moving furniture or planters. For roof terminations, confirm access to the attic or roof as required. Secure pets and let the technician know about any prior repairs or unusual duct routing you are aware of.

Maximizing the benefit after cleaning

After a thorough service, help your system stay clean by emptying the lint filter after every load and washing it occasionally to remove product residue. Step outside while the dryer runs to confirm that the damper opens fully. Keep vegetation and snow clear of the exterior hood. Make sure the dryer is reinstalled with enough clearance so the transition connector is not crushed when you push the unit back.

Interpreting proposals without confusion

Clarity is your friend. A helpful proposal outlines the steps included in the visit and notes any anticipated access considerations. It explains how the technician will confirm improvement and what kind of documentation you will receive. If there are optional recommendations—such as replacing an outdated transition or resealing joints—the proposal should describe why these suggestions matter for safety and performance.

Common questions about scope and scheduling

Homeowners often ask how long the visit will take and whether roof access is needed. The answer depends on your vent’s length, number of bends, and termination type. Straight wall terminations usually go faster; long interior runs and roof caps require additional tools and time. Scheduling is typically straightforward, but you should be available to provide access and review the results at the end.

Why routine maintenance matters

Lint accumulation is an ongoing process because laundry creates lint every day. Routine maintenance keeps that buildup in check, supports steady airflow, and helps prevent overheating. A consistent schedule, adapted to your household size and vent complexity, delivers smoother laundry days and more predictable performance. Many New Jersey households combine good habits with recurring professional dryer vent cleaning to maintain optimal results across the seasons.

Frequently asked questions

Q: What influences the scope of a visit? A: Vent length, number of bends, termination type, materials in use, and access needs are primary factors. The dryer’s internal lint pathways also play a role.

Q: Do I need to be home during the appointment? A: Yes. You should be available to provide access, answer questions, and review the results and recommendations.

Q: Will cleaning help if my dryer runs hot? A: Restoring airflow can reduce heat buildup and shorten cycle times, which eases strain on the appliance.

Q: Can a vent terminate indoors? A: No. The exhaust should discharge to the outdoors through a proper termination with a backdraft damper.

Q: What materials are recommended? A: Rigid metal for the main run and semi-rigid metal for the short transition behind the dryer are commonly advised.

Q: How often should maintenance be scheduled? A: Many homes plan for an annual visit and then adjust based on use and performance.

Ready for a clearer, safer laundry day

A well-designed proposal and a thorough cleaning translate into tangible benefits: a cooler laundry room, consistent drying performance, and greater peace of mind. If it has been a while since your last appointment, or you have just moved into a new place and want to start fresh, reach out to a trusted local team. Book comprehensive dryer vent cleaning and take the next confident step toward a safer, smoother-running New Jersey home.